Yifuku

T-shirt printing made easy

Let us show you how your product come to life.

Services

What is DTG ?

Direct to Garment (DTG) printing is a modern textile printing method that allows for high-quality, full-color designs to be printed directly onto fabric. Unlike traditional screen printing, which requires separate screens for each color, DTG uses specialized inkjet technology to apply ink directly onto the garment. This process enables detailed and vibrant prints, making it ideal for intricate designs and smaller production runs. DTG printing is highly efficient and versatile, allowing for quick turnaround times and the ability to print on demand, making it a popular choice for custom apparel businesses and clothing startups. One key point to note is that DTG printing can only be applied to cotton fibers, ensuring the best quality and durability for your designs.

DTG Process

Below are the steps for our DTG printing process.

-

Preparing for the Design

We accept all kind of pixel or vector images that have high resolution. We recommend that you provide us TIFF, PSD, AI, PDF or high-quality image files. -

Applying a coat on the T-shirt

We will treat the garments with a pre-treatment liquid to ensure the t-shirts are ready to absorb the DTG ink and protect the print, making it durable and vibrant. -

DTG Printing

We will dry the garment after pre-coating and the t-shirts will be printed by the DTG inkjet printer. More than 3 T-shirts can be printed at the same time. -

Heat Protection

After printing out the T-shirts, we will apply a temperature around 145 degree to fully dry up the water based ink. This is another layer of protection for the printing and makes it more durable.

Services

What is DTF ?

Direct to Film (DTF) printing is a cutting-edge textile printing technique that offers high-quality, full-color designs by transferring prints from a specialized film to fabric. Unlike traditional screen printing, which requires separate screens for each color, DTF uses advanced technology to print the design onto a film, which is then applied to the garment. This process ensures vibrant, durable prints, making it ideal for intricate designs and various fabric types.

DTF Process

Below are the steps for our DTF printing process.

-

Preparing for the Design

We accept all kind of pixel or vector images that have high resolution. We recommend that you provide us TIFF, PSD, AI, or high-quality image files. -

Adhesive Powder Application

A fine adhesive powder is applied to the printed film, ensuring the design adheres firmly to the fabric. -

Curing

The film with the adhesive powder is then cured to activate the adhesive properties. -

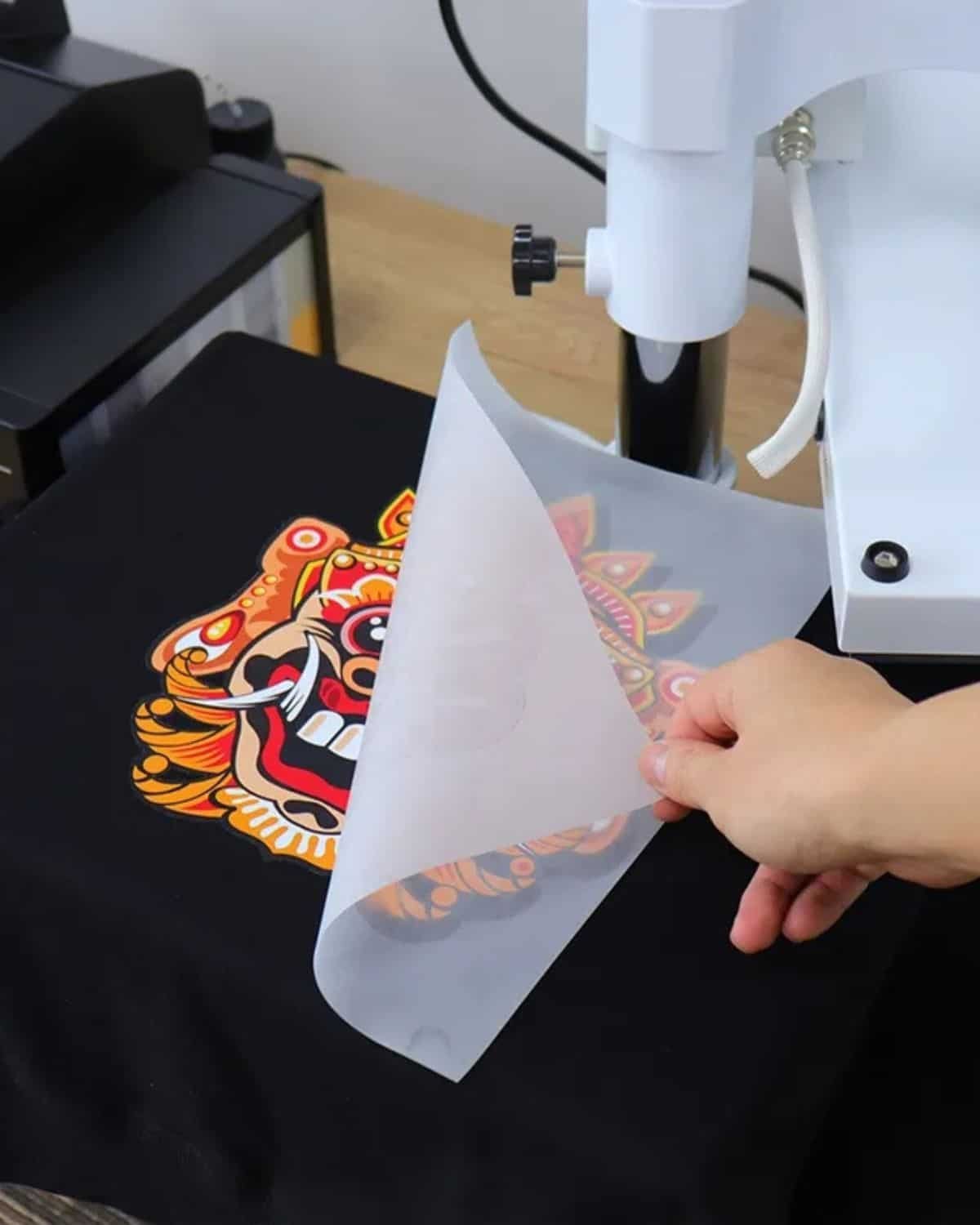

Transfer Process

The cured film is placed onto the fabric, and heat is applied using a heat press, transferring the design from the film to the garment. -

Peeling

Once the transfer is complete, the film is peeled away, leaving behind a vibrant and durable print on the fabric.

Services

What is Silkscreen ?

Silkscreen printing, also known as screen printing, is a traditional and widely-used method for creating high-quality, durable designs on t-shirts. This technique involves using a mesh screen to transfer ink onto the fabric, one color at a time. Each color in the design requires a separate screen, making silkscreen printing ideal for bold, vibrant designs with limited color palettes.

Silkscreen service required a minimum order of 50pcs.

Services

What is Embroidery ?

Embroidery is a classic and sophisticated method of decorating t-shirts that involves stitching designs directly onto the fabric using needle and thread. This technique adds a textured, three-dimensional quality to the design, giving it a premium and elegant appearance.

Embroidery service required a minimum order of 50pcs.